Decrypt Kexin Technology Smart Factory

Time:2024-04-17 14:15

Series:

Author: keixn

Source: kexin

"4G changes life, 5G changes society", 5G is striding towards us, it will open a new era of universal interconnection and human-machine interaction with high speed, ubiquitous network, low power consumption and low latency. Kexin Technology has ushered in a new opportunity to focus on the ICT field, focusing on 5G, IoT (Internet of Things), IDC (data center) technology breakthroughs, and actively developing the industrial layout of infrastructure and industry applications in various fields, forming the four major Solutions (optical communication network solutions, Internet of Things solutions, communication network energy solutions, data center solutions), making people communicate more easily, people and things are more intelligent, and people are more intimate with the world. .

In order to effectively support the company's strategic goals, accelerate industrial transformation and upgrading, the supply chain has deepened the intelligent model, “committed to quality, cost, efficiency, flexibility, agility, integration, and create an excellent supply chain with comprehensive competitive advantages and Kexin characteristics” Through the in-depth application of the "two-in-one integration" management system, it analyzes the multi-dimensional analysis of people, machines, materials, methods, and rings to improve the level of warehouse management, production management, quality management, program management, and equipment management.

Industrialization and informatization are important targets for the transformation and upgrading of manufacturing industries, and are effective tools for improving product quality and production efficiency. Kexin Technology gradually realized intelligent manufacturing through the deep application of “two-in-one integration” and built a unique transparent factory. Now let us walk into Kexin Technology and get to know the smart factory of Kexin Technology.

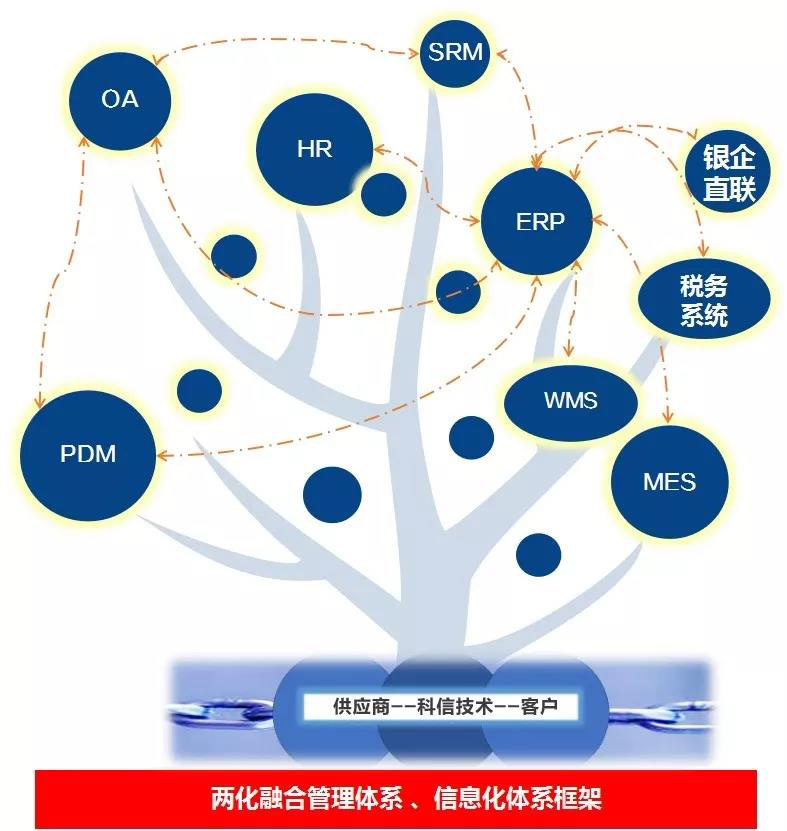

1. Building an information system to create a framework for Kexin's technology information system, reducing operating costs and improving delivery efficiency

Kexin Technology builds a transparent factory management platform through information system, adopts “Internet +” technology, and combines “two-in-one integration” management system, from the infrastructure layer, business operation layer, management and control platform layer to analysis and decision-making layer, and gradually establishes information. System framework. Based on HR, OA, SRM, PDM, MES, ERP, E-message and other systems, the company has formed an information management system with the characteristics of Kexin. The external link has been opened from the supplier to the client, and the sales, R&D and supply have been opened internally. Chains and links within each system to achieve centralized management and key monitoring of the entire process between Shenzhen and Huizhou and other manufacturing bases and suppliers, to help the company's management model change, improve sales, development, procurement, planning, production, The relevant links of warehouse and logistics work together to achieve rapid delivery of orders as a whole.

Second, with barcode as the carrier, build a quality management system with “reliable quality”, “process controllable” and “result traceability”

The digital management of product information must be fully barcoded from the raw material level of the supplier, laying a digital foundation for the whole process of inventory management, quality management and product realization. Through the data collection of the whole process (raw material to semi-finished product to finished product), real-time monitoring of people, machines, materials, methods and loops can be realized to ensure that the quality range can be analyzed and the effective range can be quickly filtered out through various dimensions. And deep and transparent analysis, find the real cause of abnormalities and defects, quickly determine the boundaries of responsibility and effectively deal with them. The quality management system monitors the status of quality indicators in real time, and achieves effective tracking, analysis improvement and closed loop when quality anomalies are achieved. Through the trigger mechanism of email alert, SMS sending and APP warning, the benign situation of product quality control and continuous improvement is ensured.

Product life cycle quality is reversed

Third, through the WMS management system, promote the refined management of the warehouse, to create a visual, transparent, digital intelligent storage

Realize the combination of dynamic and static position management: the warehouse is changed from static management to dynamic management. The materials can be placed in any free location, the system intelligently identifies the relevant information, and automatically indexes the material to increase the flexibility of location management. At the same time, the warehouse strengthens the control of special materials. For example, electrostatic materials must be placed in the static area. Materials with temperature and humidity requirements must be placed in a constant temperature and humidity zone, thus forming a warehouse management mode combining dynamic and static.

Location management

The implementation process automatically triggers but prevents each other: the system triggers the material inventory when the supplier comes in, and can automatically trigger the IQC test. Strictly prevent the stagnation on the process, the unqualified products are not allowed to enter the warehouse, the upper position is not allowed, and the delivery action is not allowed. At the same time, the review mechanism can be triggered to speed up the product transfer efficiency.

Receiving management

Achieving on-demand pull: taking the plan as the leader and the production rhythm as the trigger point, the warehouse and the production workshop form a relative JIT mode, and the production site is half warehouse.

Issue management

Realize first-in, first-out, foolproof control, automatic indexing, overdue re-examination, etc.: Originally relying on auditing, relying on management to achieve first-in, first-out, now system-defense, automatic indexing materials in accordance with the principle of first-in, first-out; original relying on memory and familiarity Looking for materials, the system automatically indexes the location; the original management relies on the expiration re-examination, resulting in the expiration of many high-value materials. Now the system automatically triggers the re-inspection, and the inspection can only be re-stocked.

Smart storage

Fourth, promote lean transformation projects, introduce lean management model, and comprehensively improve management level

In addition to promoting management information and equipment automation, the company also vigorously promotes lean management, introduces and implements a variety of advanced management tools and concepts, improves the job site through the introduction of 7S management, and transparentizes management through Kanban (kanban management). Through QCC (Quality Control Circle) to create a continuously improved soil, through TPM (Comprehensive Production Maintenance), equipment, tooling, appliances, etc. are in full lifecycle management state, and electronic production and inspection instructions are electronically implemented through eSOP and eSIP. Total quality management through TQM and comprehensive safety production management through WSS. In short, we will lay a good management foundation for the construction of smart factories by promoting lean reform.

Kexin Technology Practices through continuous integration of innovation and management, and promotes the spirit of craftsmen. Customer-oriented, close to customer needs, to provide customers with high-end products and high-quality services. As an important part of the value chain, Kexin Technology strives to build a production plant into an intelligent and transparent factory, contribute to the transformation and upgrading of China's manufacturing industry, and explore a successful road for private enterprises.

More news

Kexin gathers strength to move forward and fully enter the international household savings market!

Kexin Juli is committed to improving the industrial layout in the field of energy storage, and continues to provide customers with professional energy storage system solutions.

2022/07/06

Good news! Kexin Technology was rated as a "specialized, special and new" enterprise

Recently, the Shenzhen Municipal Bureau of Industry and Information Technology announced the list of "specialized, special and new" small and medium-sized enterprises in 2021. The accumulated comprehensive strength has successfully entered the list of "specialized and special new" enterprises, which is another scientific and technological innovation certification of the company after passing the previous "high-tech enterprise" certification.

"Specialized, refined and innovative" is a major project implemented by the state to promote the specialization, refinement, specialization and novelty of SMEs, enhance independent innovation and core competitiveness, and improve the development quality and level of SMEs. Enterprises that are cultivated, selected and supported are usually leaders who focus on market segments, focus on key technologies, strong innovation capabilities, good growth, high market share, and excellent quality and efficiency. The resilience of the industrial chain and supply chain plays an indispensable and important role in strengthening, complementing and stabilizing the chain.

The award of "specialized, refined and new" enterprises this time is also a full affirmation of the technology, products and services of Kexin Technology over the years by the competent authorities, professional institutions, industries and customers. Kexin Technology adheres to innovation as the driving force for development. Since its establishment in 2001, it has been deeply engaged in the field of ICT, focusing on technological breakthroughs in 5G, IoT and IDC. It has more than 300 patents and over 60 computer software copyrights. Member, leading or participating in the drafting and revision of more than 50 national and industry standards.

As a provider of professional communication equipment manufacturing, services and solutions, Kexin technology product research and development involves site energy, data center, communication energy storage and other aspects, and the service system fully covers 32 domestic provinces and cities and many important economies around the world In the region, related products have been successfully implemented in communications, transportation, education, medical care, finance, agriculture, real estate, exhibition and other industries.

In the future, Kexin Technology will continue to practice the development path of "specialization, refinement and innovation". By increasing investment in scientific research, improving technological innovation capabilities, strengthening professional personnel training, consolidating the core competitiveness of enterprises, and creating more for customers and investors value, and make greater contributions to the development of global communications.

2022/06/27

Kexin Technology will actively embrace carbon neutrality, focus on customer needs, continue to maintain technological iterations and innovative breakthroughs, and explore more and better solutions to help enterprises in their digital and green transformation. Scenarios and better practices, join hands with thousands of industry partners to move forward bravely, and move towards a green future together!

2022/04/20

Follow us

Stock Code:300565

Copyright©Shenzhen Kexin Communication Technology Co., Ltd.